How Medtronic Simplifies Insulin Dosing with ProtoPie

Learn how Medtronic uses ProtoPie to streamline insulin-dosing solution prototyping.

Prototyping is crucial in the MedTech industry because it bridges the gap between the initial design and the final product, ensuring safety, efficacy, and user-friendliness. Prototypes help identify and resolve potential issues early through iterative testing and refinement, thus enhancing product reliability. This process is essential for meeting regulatory standards and speeding up development timelines, ultimately reducing costs and time to market.

This blog article will discuss prototyping for MedTech, focusing on using ProtoPie to prototype diabetes management solutions. We will highlight a recent live stream session with industry leader Medtronic, where Brian Tackle, Principal UX Designer at Medtronic, shared insights on prototyping simplified insulin dosing solutions.

For those unable to attend the live event, we invite you to watch the recording below.

Overview

- Medtronic’s approach to prototyping

- Medtronic’s prototyping workflow

- Why Medtronic adopted ProtoPie in their prototyping flow

- Benefits of using ProtoPie for MedTech prototyping

- Q&A with Brian Takle

Medtronic’s approach to prototyping

Brian Tackle, a seasoned UX designer with over 20 years of experience, took the stage to discuss Medtronic's approach to simplifying insulin dosing solutions through effective prototyping. Medtronic is a global leader in healthcare solutions, with a dedicated team focused on designing and testing patient-facing applications for diabetes management.

Brian detailed the workflow of Medtronic’s Customer-Centered Design (CCD) group, which focuses on:

- UX Design

- Prototyping

- Formative and summative testing

- Patient acceptance & success

- Risk reduction/mediation

The CCD group ensures that all patient-facing applications are user-friendly and effective in helping people manage their diabetes.

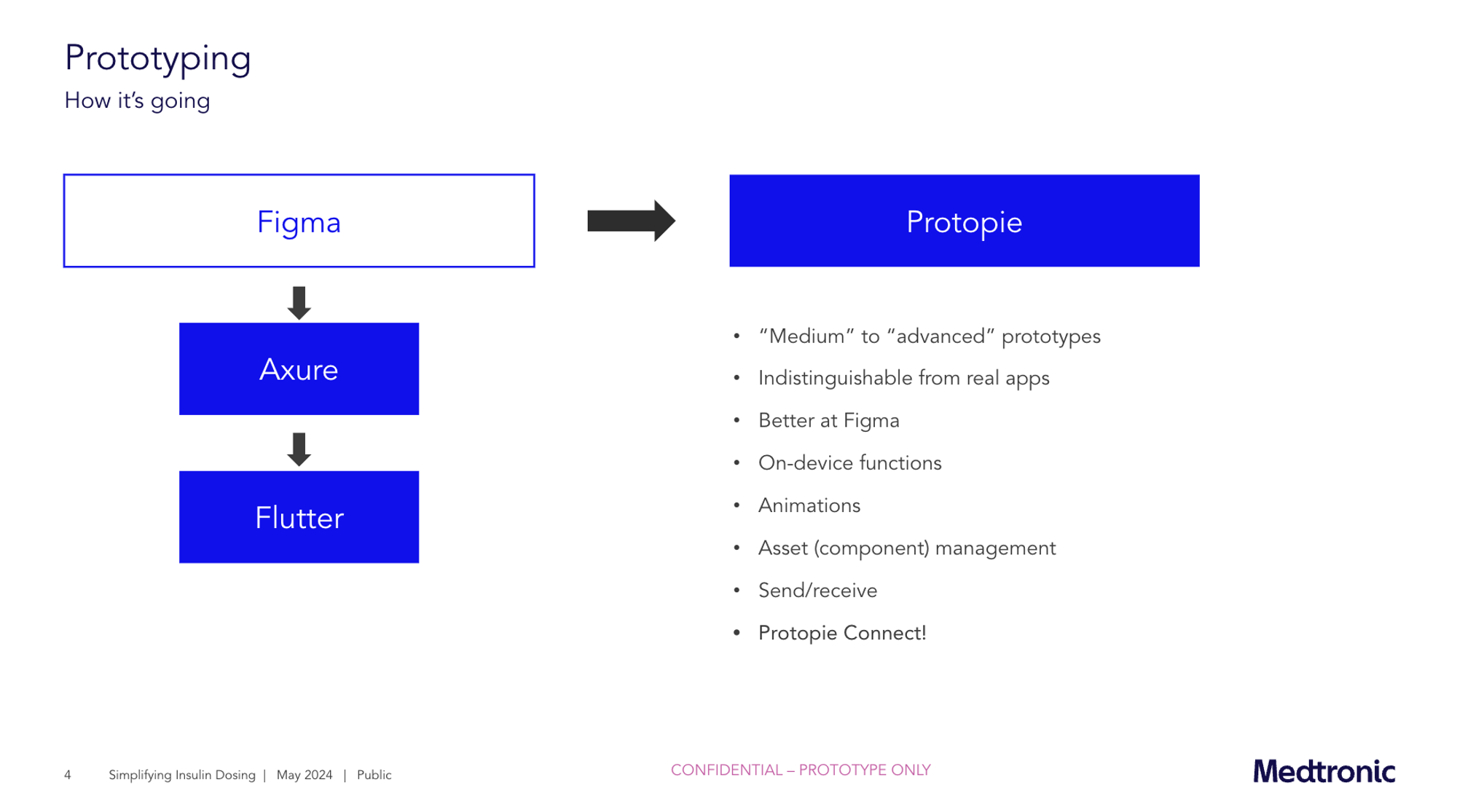

Medtronic’s prototyping workflow

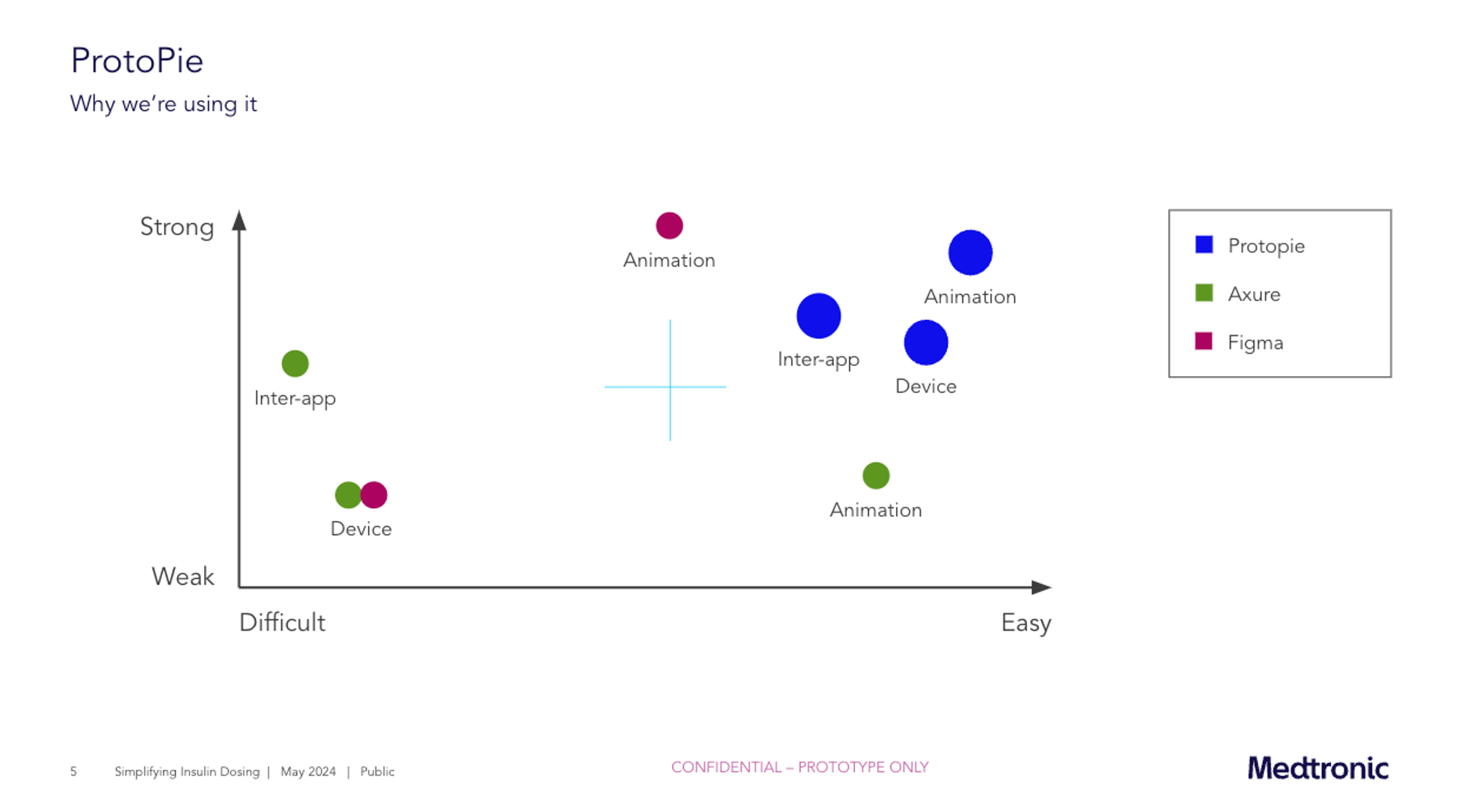

Brian explained Medtronic's initial prototyping process, which involved creating designs in Figma for user flows, UX/UI design, basic prototyping, and collaboration. The designs were then exported to Axure to develop medium to advanced prototypes. However, this process changed when Medtronic found ProtoPie.

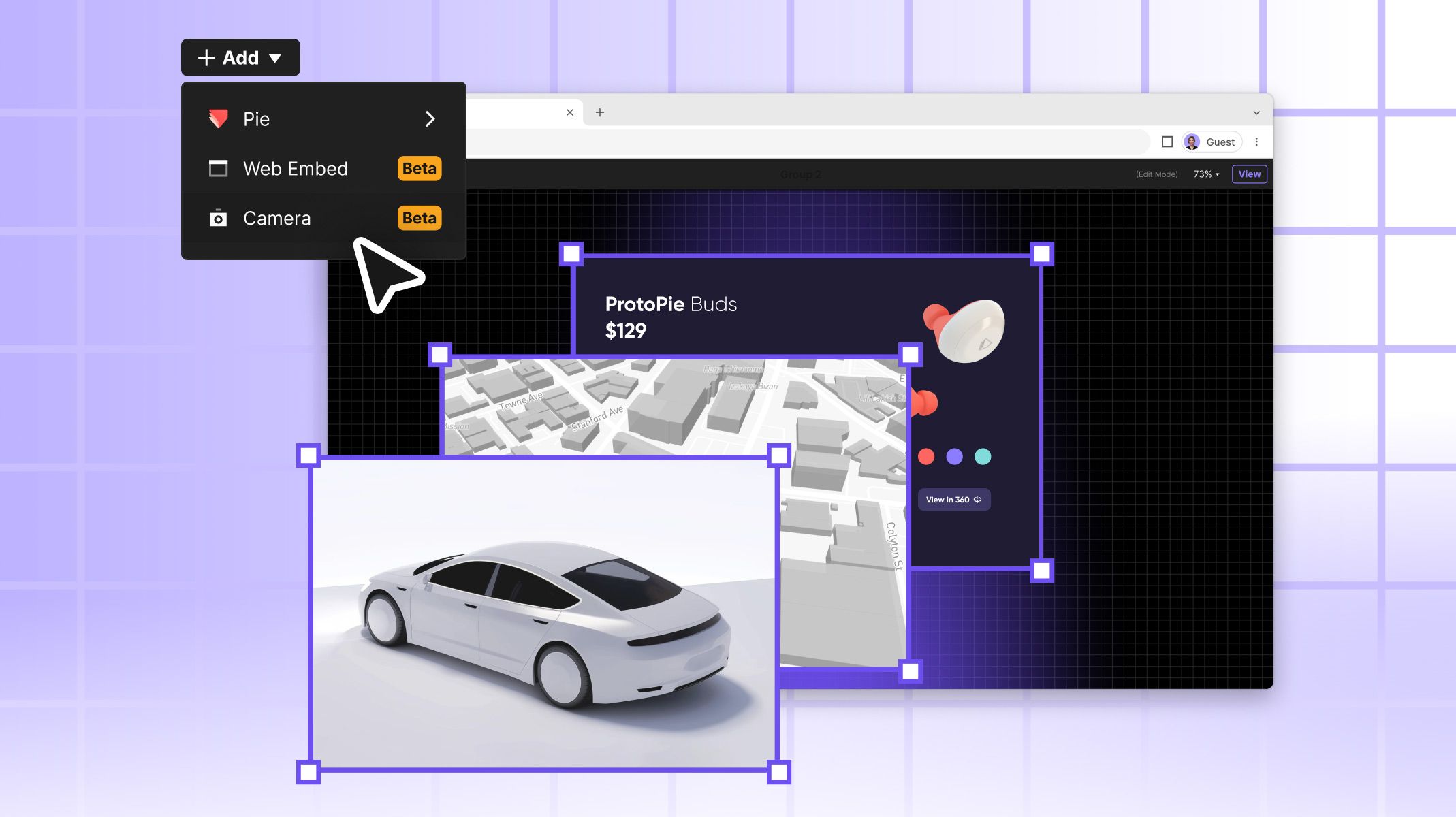

Brian explained, "We've started using ProtoPie. It does a lot of the same things that Axure does for us, but it can get pretty advanced and be indistinguishable from a real app. It's significantly better than Axure at pulling in Figma assets. Additionally, ProtoPie offers on-device functions like camera, vibration, and voice input and output, and it excels at animations. It also has a clever Send and Receive function, which we'll discuss further."

Why Medtronic adopted ProtoPie in their prototyping flow

ProtoPie offers advanced prototyping capabilities

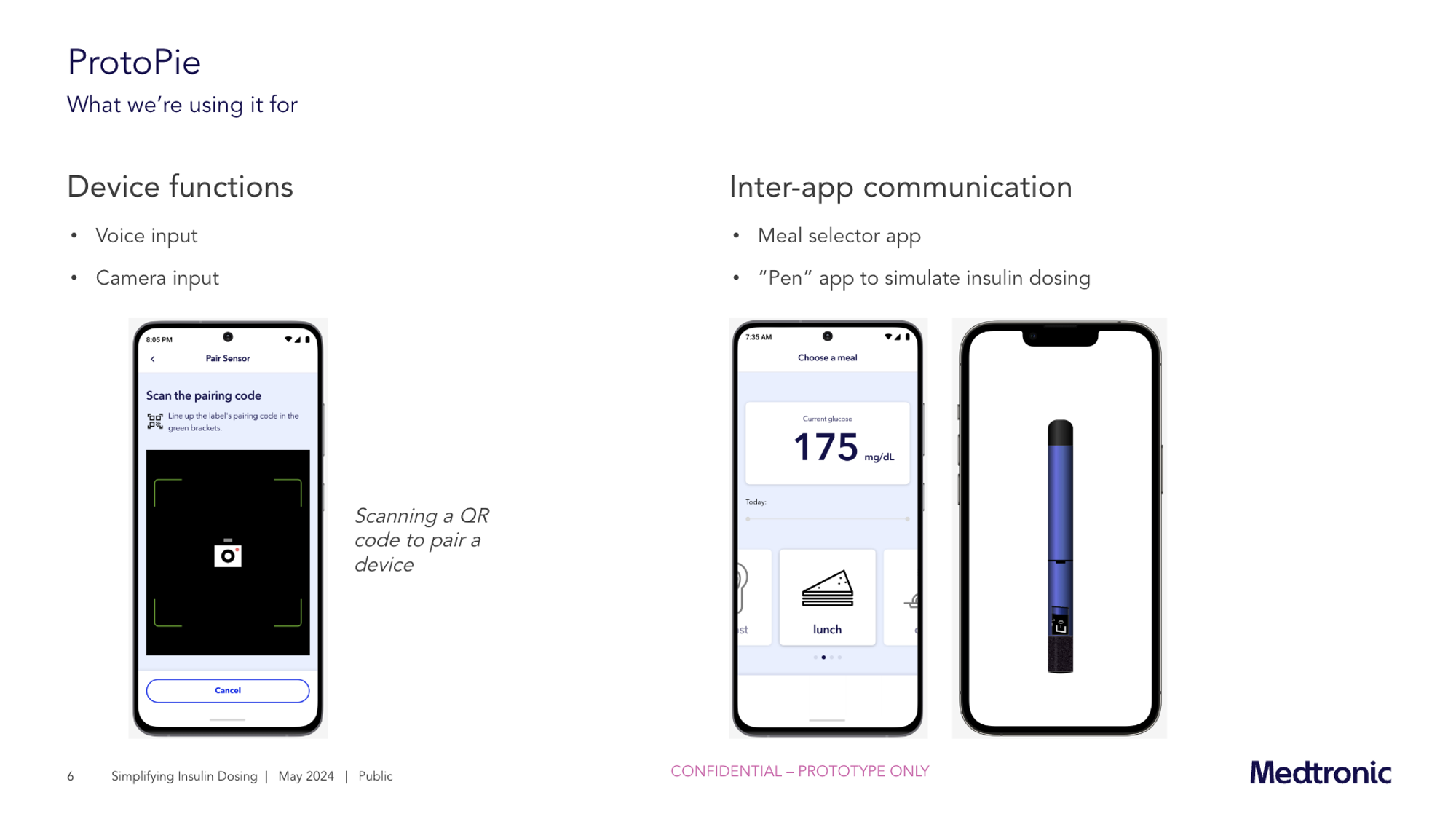

Brian demonstrated how ProtoPie can create sophisticated prototypes virtually indistinguishable from real applications. He highlighted two key examples:

- Label scanning prototype: Users can scan a label with their phone's camera to pair an external device, simplifying a previously cumbersome process.

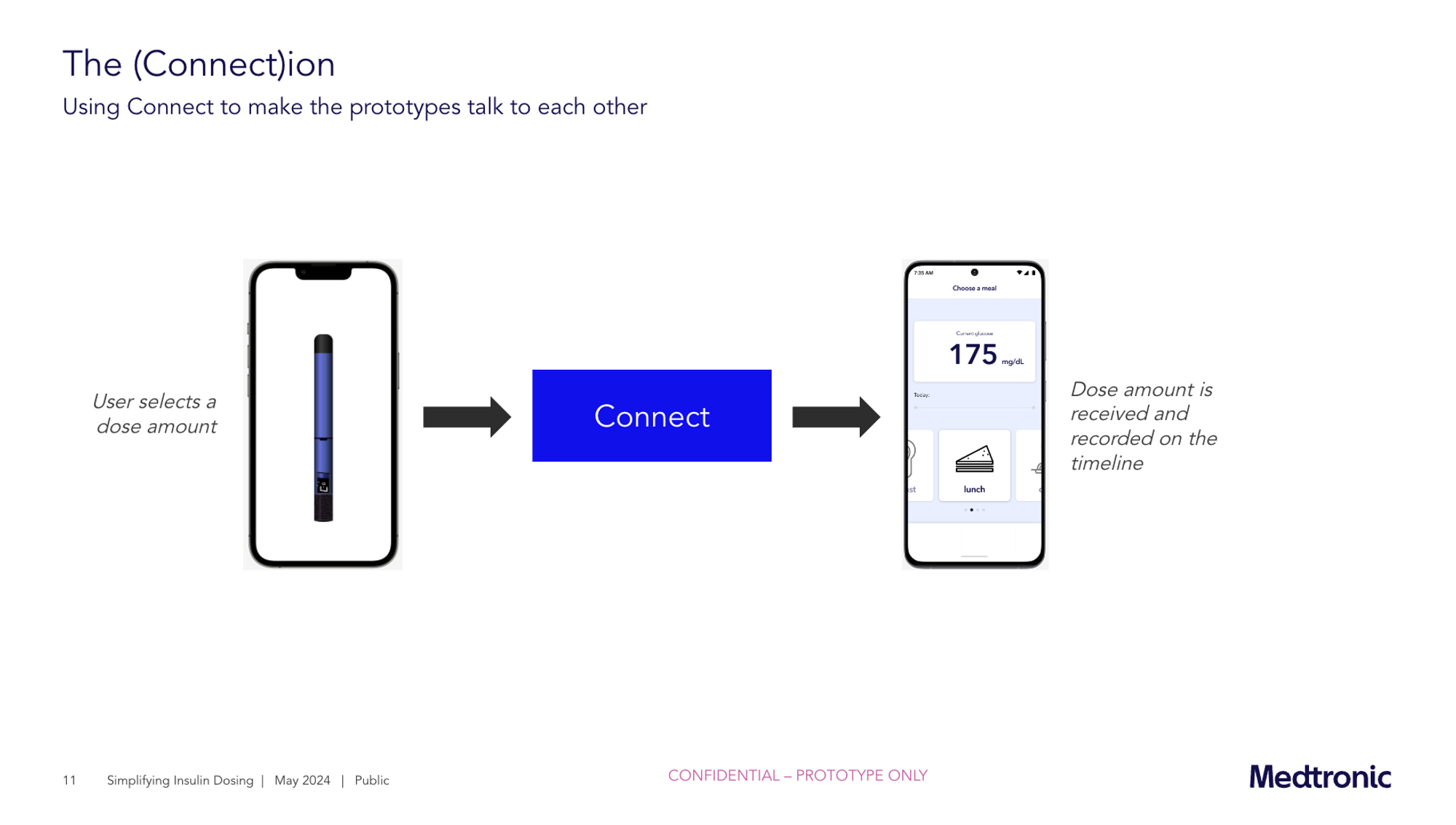

- Interaction between dosing and pen apps: This prototype shows the interaction between a dosing app and a pen simulator, utilizing ProtoPie Connect to enable seamless communication between the two apps.

ProtoPie supports on-device functions like camera, vibration, and voice

“For us, the animation features and interactive communication, along with the on-device functions, they’re really strong in ProtoPie and very easy to use,” says Brian.

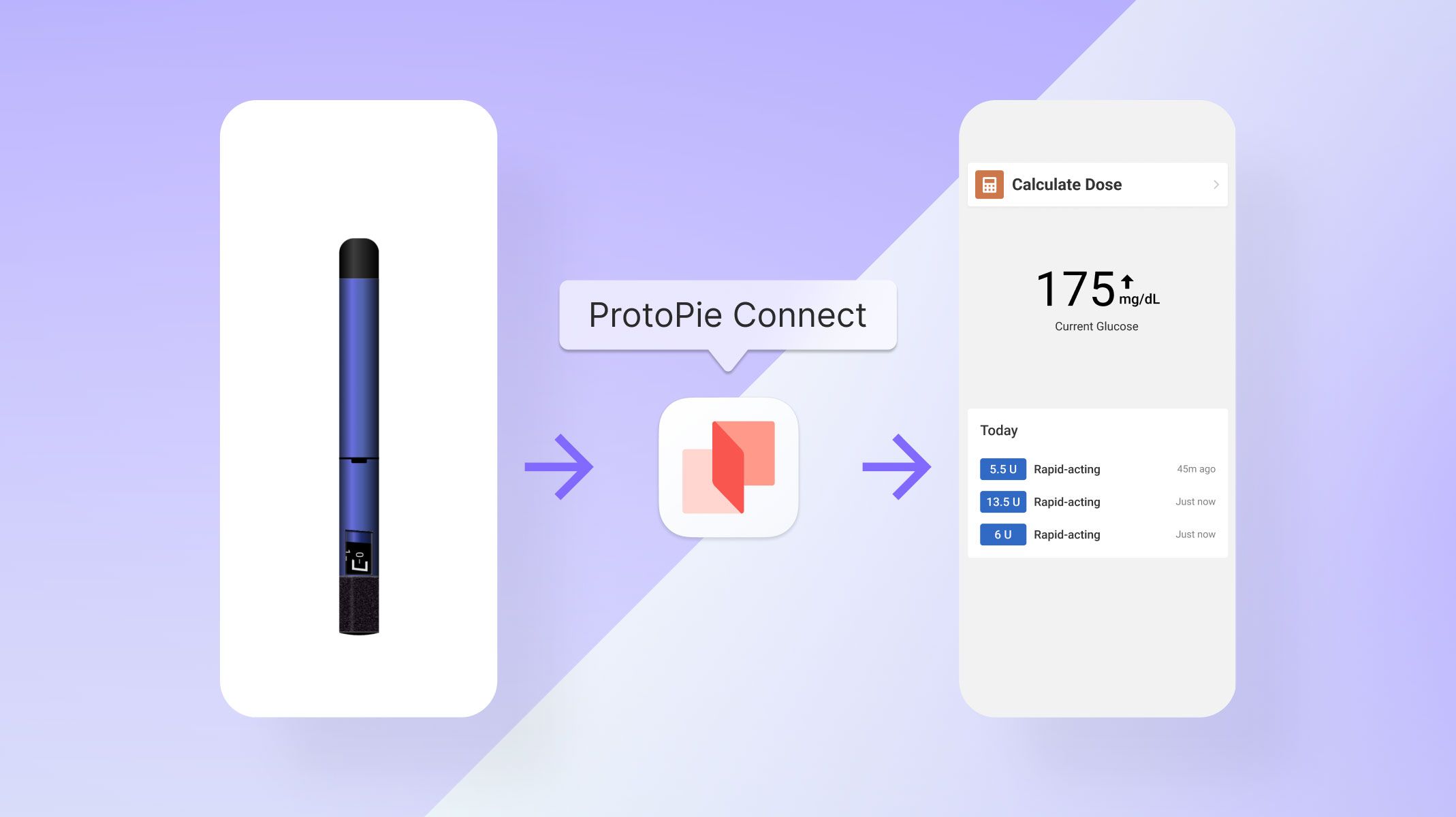

ProtoPie supports cross-device communication

ProtoPie's Send & Receive functions, which facilitate inter-device communication, and ProtoPie Connect are also among the features heavily utilized at Medtronic.

Want to learn how ProtoPie can elevate your MedTech prototyping workflow? Schedule a demo to find out more.

Managing diabetes through high-fidelity prototyping

What is a Glucose Monitoring app?

Managing diabetes requires constant awareness of factors such as current blood glucose levels, food intake, carbohydrate content, and insulin dosage. To ease this burden, many diabetes patients now use smartphone apps for glucose monitoring. These apps, connected to sensors, provide real-time blood glucose readings and help users determine when and how much insulin to take. This technology eliminates the need for frequent finger pricking and manual calculations, making diabetes management more convenient and accurate.

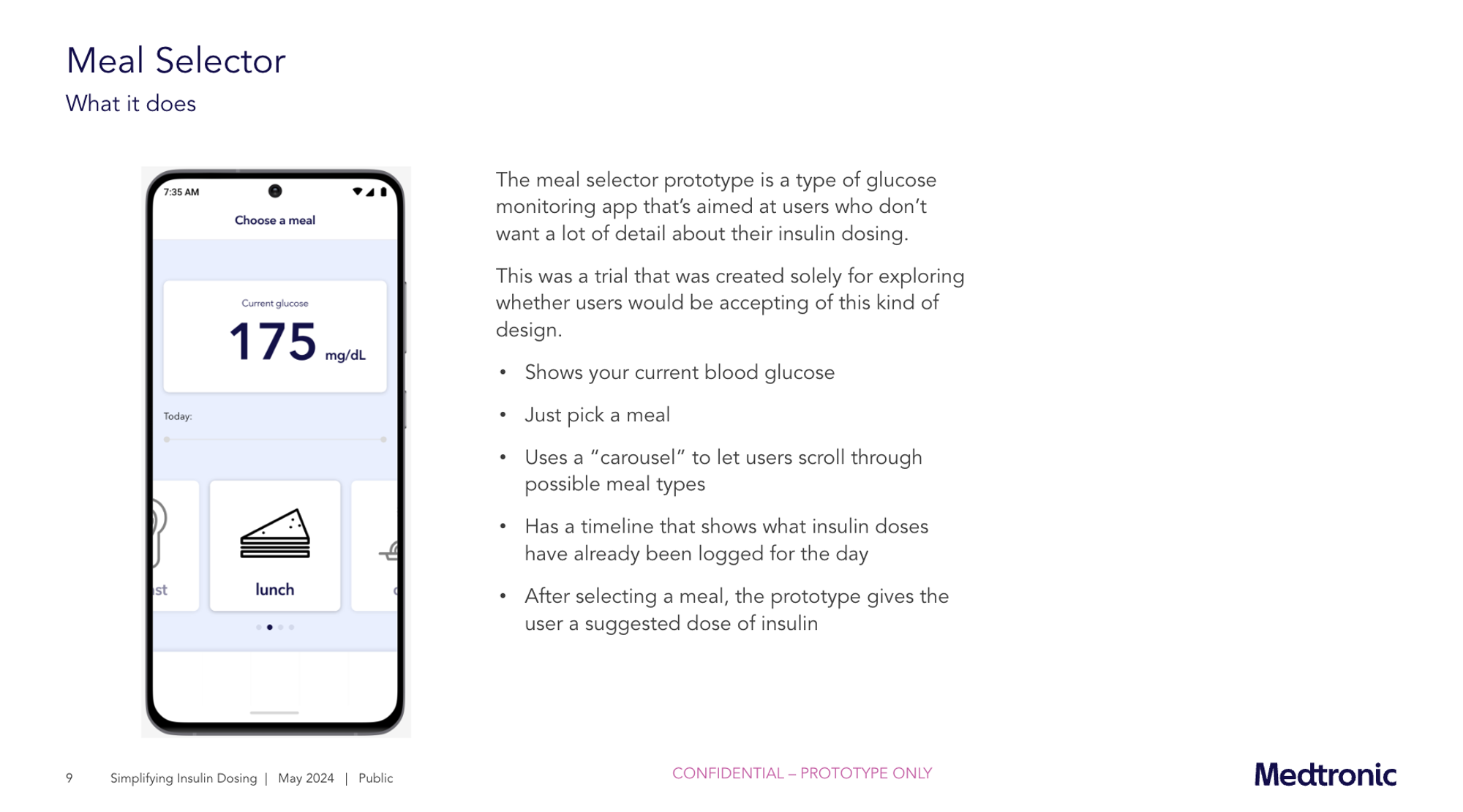

What is a Meal Selector, and what does it do?

Brian discussed the meal selector prototype, a simplified glucose monitoring app intended for users who prefer minimal detail about their insulin dosing. The trial aimed to assess user acceptance of this design. The app displays the current blood glucose level, allows users to select meals via a carousel interface, and includes a timeline of logged insulin doses for the day.

After a meal is chosen, the prototype suggests an appropriate insulin dose.

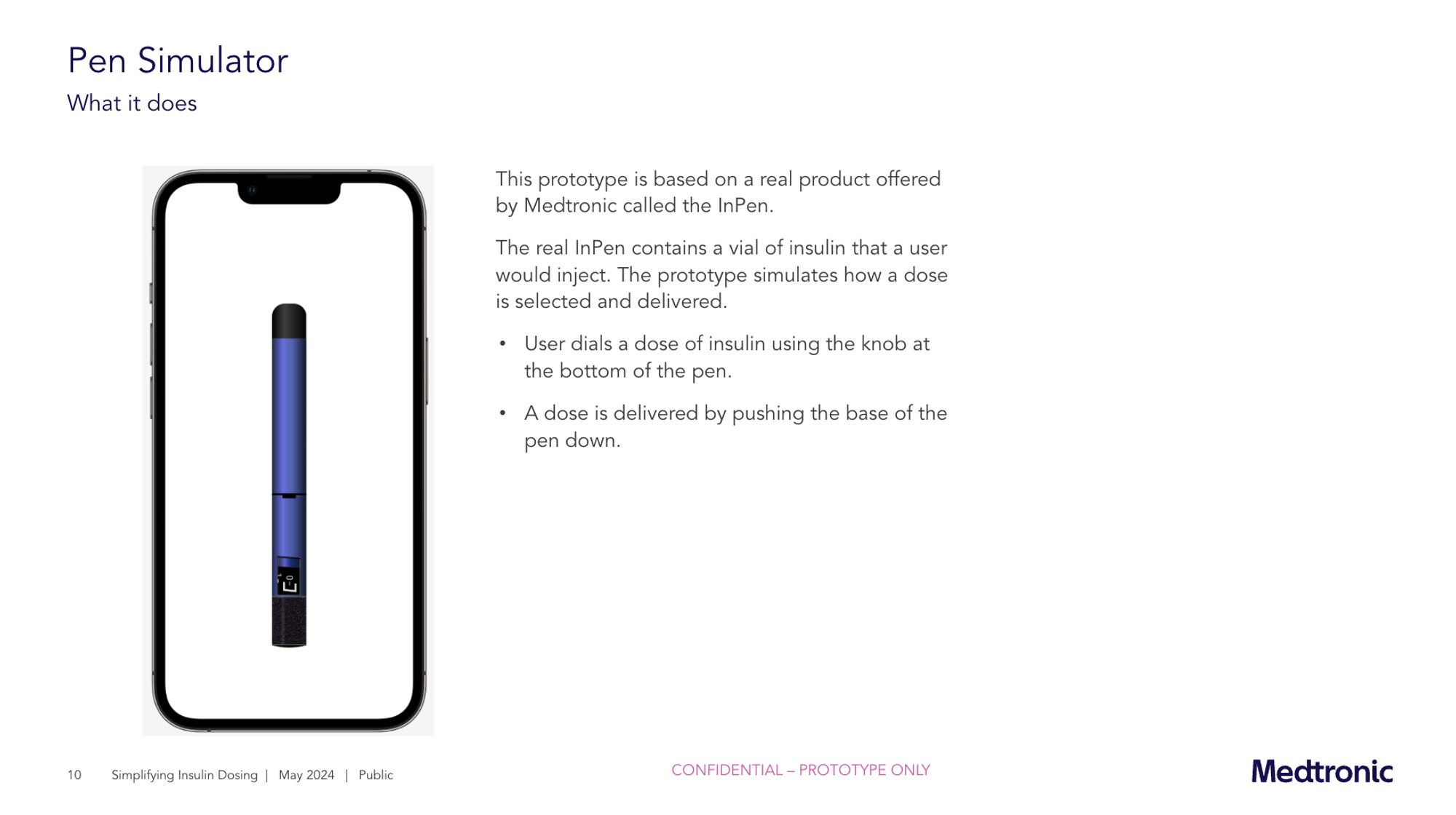

What is a Pen Simulator, and what does it do?

This prototype is based on Medtronic's real product, the InPen. The InPen contains a vial of insulin for injection, and the prototype simulates selecting and delivering a dose. Users dial the insulin dose using a knob at the bottom of the pen, and the dose is delivered by pushing down the base of the pen.

Connecting the Meal Selector and the Pen simulator using ProtoPie Connect

The highlight of the session was Brian’s demonstration of ProtoPie Connect. Connect allows different prototypes to communicate with each other, enabling advanced interactions and real-world simulations. Brian showed how the dosing app (meal selector) could send a dosage recommendation to the pen app, which then returned the administered dose, demonstrating ProtoPie Connect's powerful capabilities.

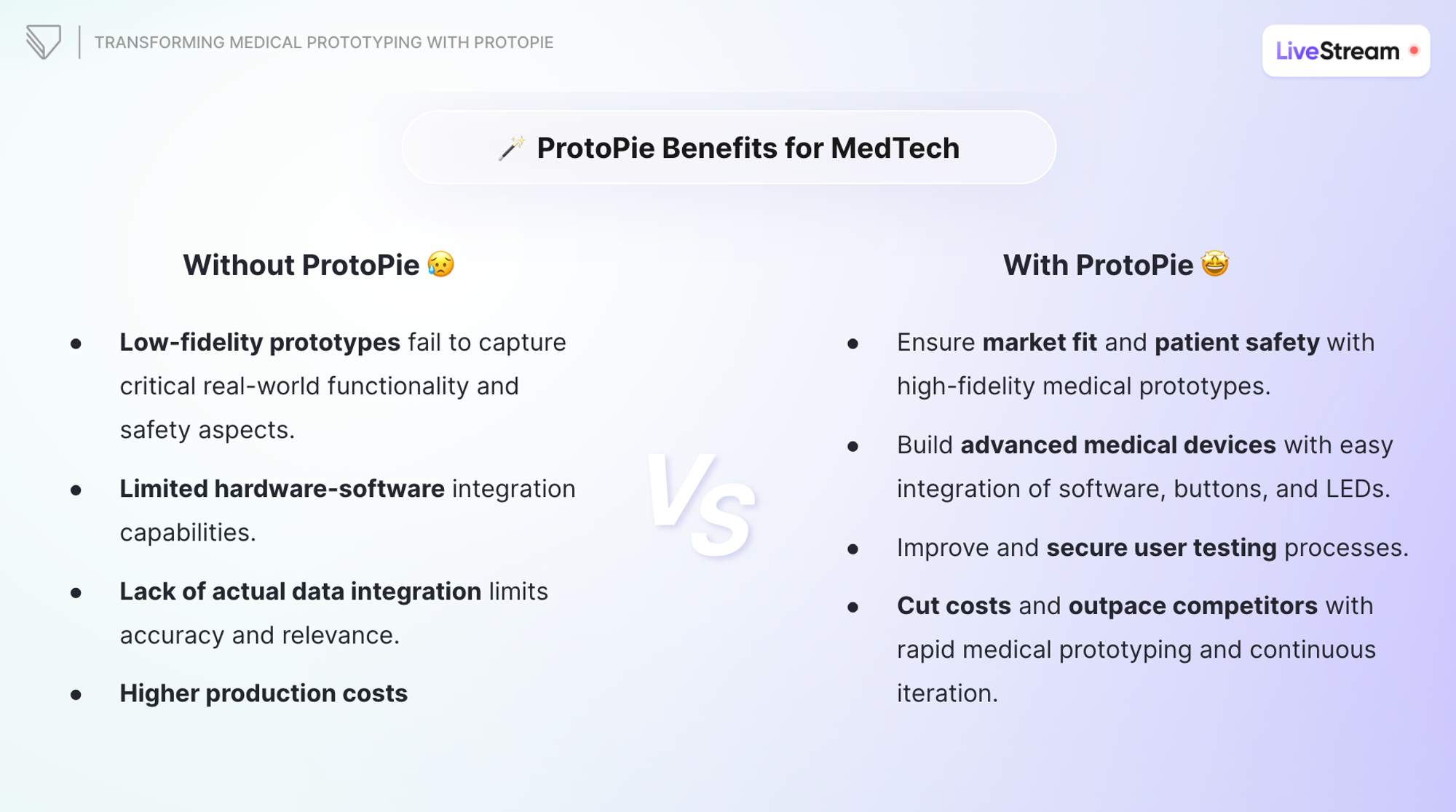

Benefits of using ProtoPie for MedTech prototyping

Following Brian’s presentation, Tim Crouse, Business Development Manager at ProtoPie, discussed the broader benefits of using ProtoPie for medical prototyping. He emphasized several key points:

Ensuring market fit and patient safety

Tim highlighted the importance of high-fidelity prototypes in ensuring market fit and patient safety. ProtoPie allows designers to create realistic prototypes that can be thoroughly tested, providing valuable feedback to refine the product.

Enhanced interaction capabilities

ProtoPie's ability to interact with external hardware and data sources sets it apart from other prototyping tools. This feature is crucial for medical devices, where accurate and real-time data integration is essential.

Cost and time efficiency

ProtoPie’s no-code environment allows for rapid prototyping, reducing production costs and speeding up development. This efficiency is particularly beneficial in the medical field, where timely innovations can significantly impact patient care.

User testing and feedback

Tim emphasized the importance of user testing in the prototyping process. ProtoPie offers various methods for user testing, such as cloud-based and on-device testing, to ensure thorough evaluation by real users.

Q&A with Brian Takle

The webinar concluded with an engaging Q&A session, where participants asked various questions about prototyping for medical devices. Here are some highlights:

Q. Could you share how the CCD team is structured (i.e., Researchers, Industrial/Interaction Designers, Developers)? What roles are involved in this activity until you reach the point of starting to create a prototype?

Brian: Industrial design is not involved in this. The team includes interaction designers, which I refer to as UX designers, but no developers. This team hands over their work to a separate development team. Researchers and interaction designers (UX and prototyping) are all part of one team.

Q: How did you go about learning Connect? How long did it take?

Brian: I’m not really sure how I learned about Connect. I saw a problem and decided to tackle it. Some very technical people on my team introduced me to Connect. It did not take long to learn; the learning curve was not high for me.

Q: Did you have a coding background before starting with ProtoPie?

Brian: Yes and no. I was an English major but taught myself several programming languages. I am familiar with how coding works, though I would not consider myself a developer.

Q: Is the glucose monitor and the pen function two different apps? If so, why not make them all in one?

Brian: They could be all in one app. There is no significant reason they are separate; we just happened to make them two different apps and thought, "Can we make them talk to each other?"

Q: Are you conducting these user trials remotely or in person?

Brian: Primarily, these trials are done in person. We deploy prototypes directly to an app on the phone, and users can launch the prototype, which works on the phone like a real app.

Q: How do you recommend introducing and convincing a new company to leverage ProtoPie when they mainly use Figma for prototyping?

Brian: If you want to use device functions like a camera, vibration, or voice input/output, ProtoPie is unmatched. Figma is improving, but animation and advanced interactions are more challenging in Figma. ProtoPie also supports importing designs from Figma seamlessly.

Q: Do you use ProtoPie for developer handoff? What is the feedback from developers when you switch to ProtoPie?

Brian: We do not currently use ProtoPie for developer handoff; it’s a manual process at the moment. It would be cool if it could happen, but it doesn't right now.

Q: What are some potential unhappy paths in the prototypes you showed?

Brian: There are several ways things could go wrong, such as the pen not communicating with the other device or losing connectivity. The prototype is very simple and not designed to handle all potential issues.

Transforming MedTech prototyping with ProtoPie

ProtoPie and high-fidelity prototyping offer significant benefits for the MedTech industry. Creating realistic, interactive prototypes that closely mimic real-world applications allows for thorough user testing and rapid iteration. This accelerates the development process and ensures that the final product meets the high standards required in medical device design.

By utilizing ProtoPie, Medtronic has showcased how advanced prototyping tools can streamline complex processes, such as insulin dosing, ultimately enhancing patient outcomes and establishing new benchmarks in medical technology innovation. Join them and delve into high-fidelity prototyping today.

.jpg)